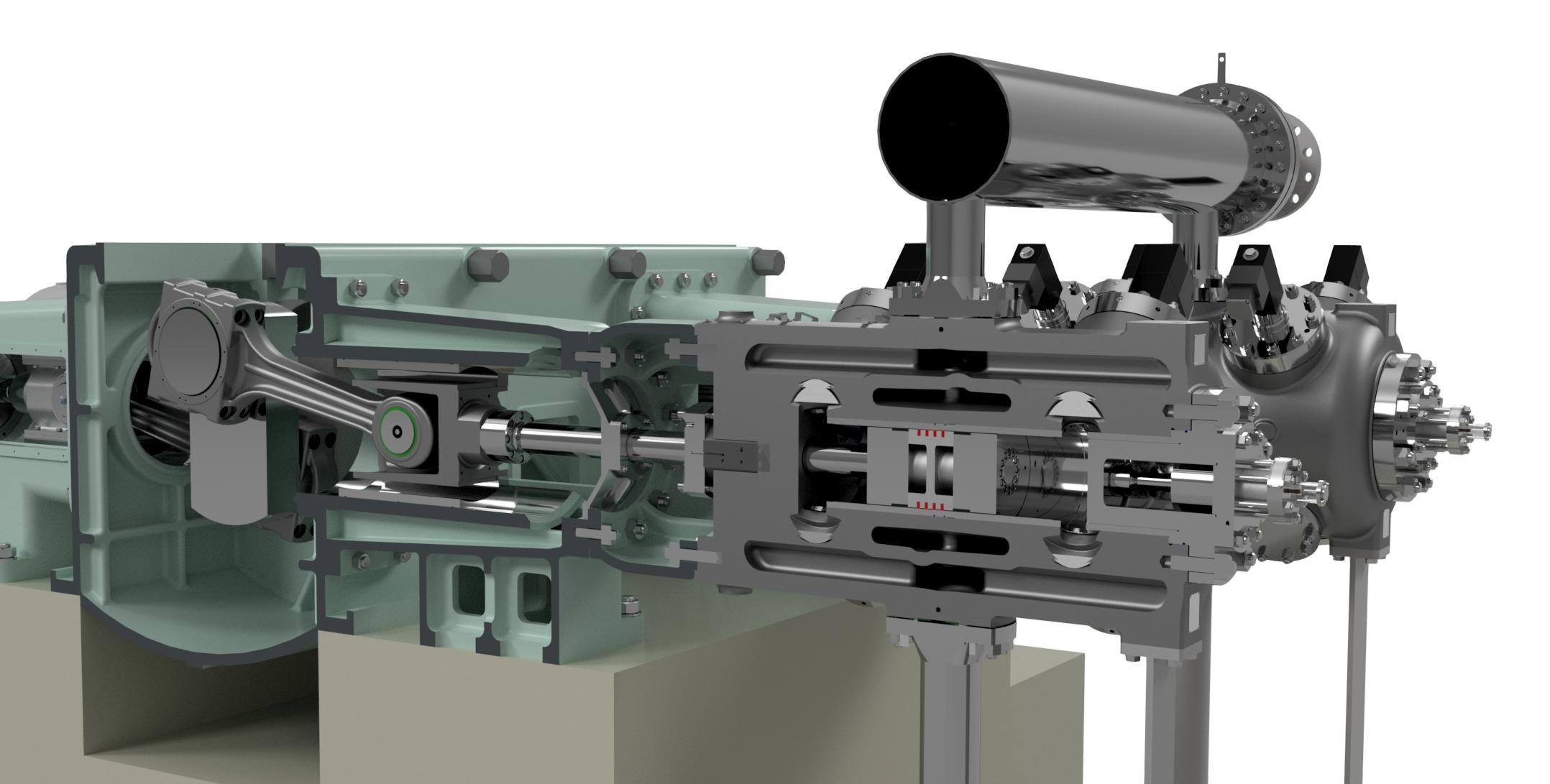

Reciprocating Compressor Modernization & Upgrading

We have the experience and knowledge to modernize and/or upgrade any part of your reciprocating compressor installation.

From an increase in capacity, to vibration solutions and from manufacturing new cylinders to oil system upgrading.

We perform mechanical and thermodynamic evaluations of compression equipment to increase capacity and/or efficiency.

We can model any compressor performance and also evaluate and update the process around the reciprocating compressor including scrubber design, cooler design and pulsation bottles.

Scope and solutions

- Process debottlenecking

- Process simulations

- Lifetime extension

- Compressor performance upgrades

- Compressor retrofits & rejuvenation

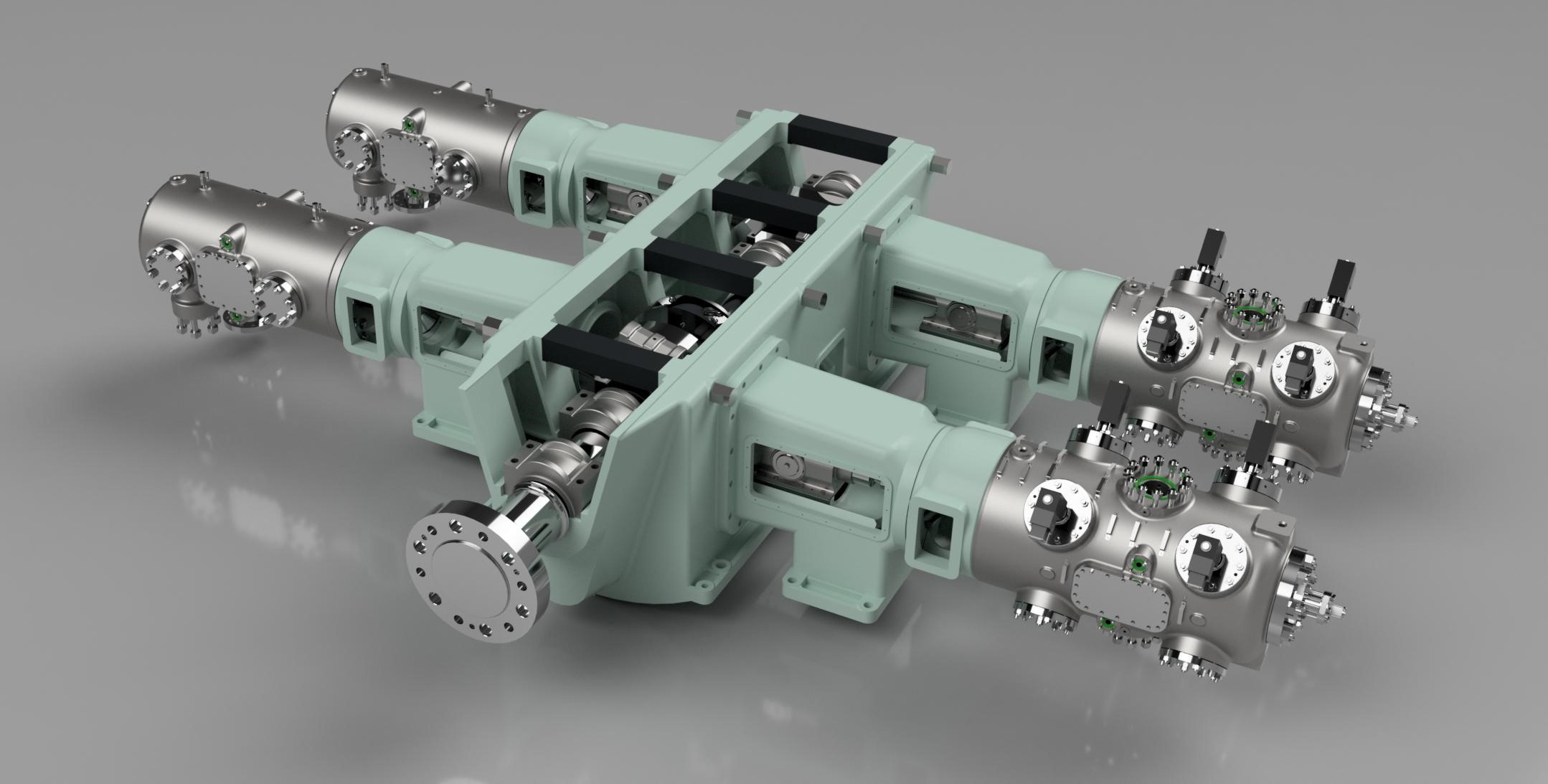

- Compressor capacity control devices

- Compressor pulsation reviews and control solutions

- Compressor performance software solutions

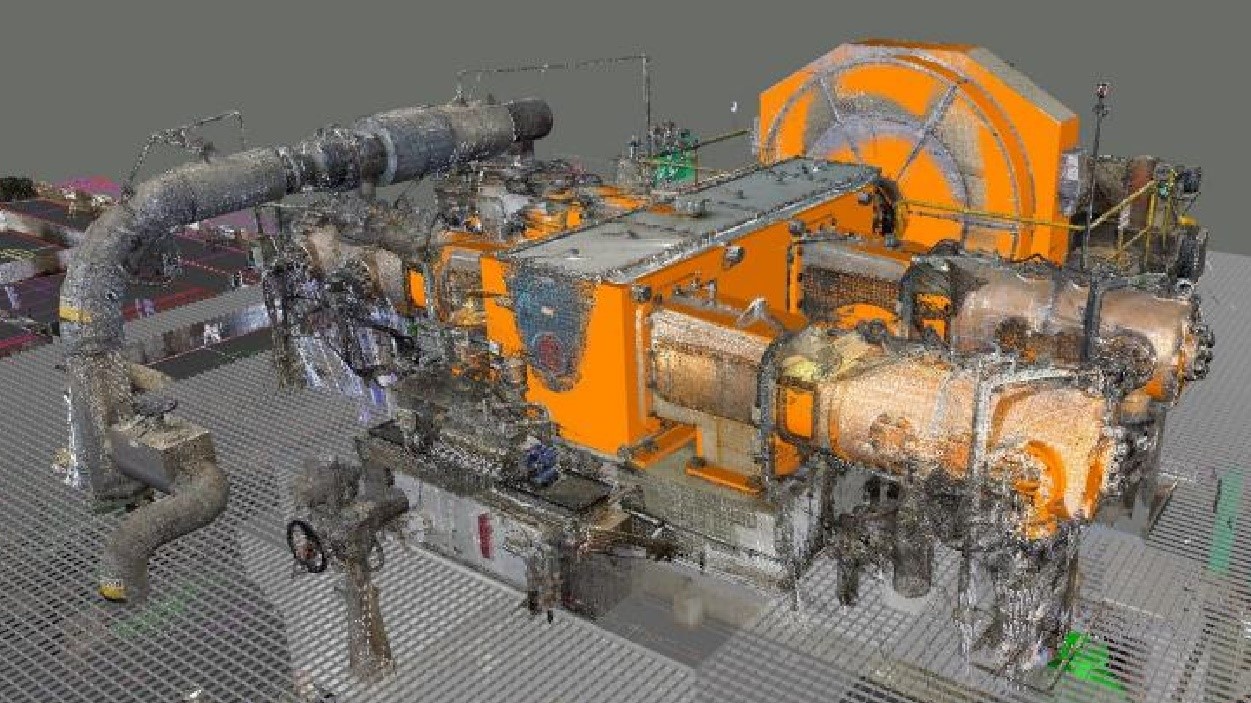

- 3D scanning & modelling

- Cylinder manufacturing

- Crankshaft manufacturing

- Compressor parts design and manufacturing

- Pulsation control devices

- Scrubber and cooler design and manufacturing

- Asset integrity management

- Risk based assessments and maintenance optimization

- Vibration studies

- Training & 3rd Party consultancy

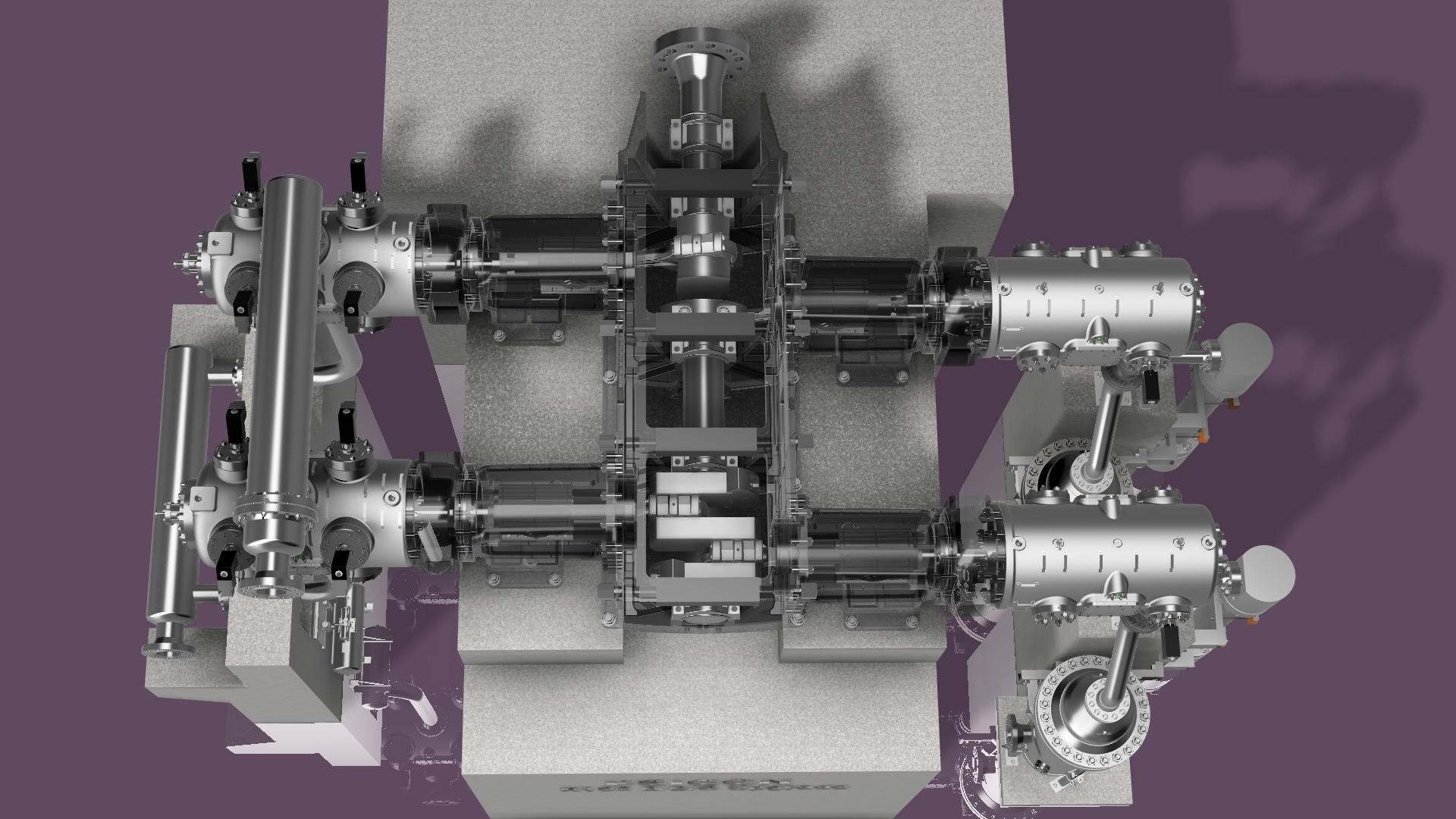

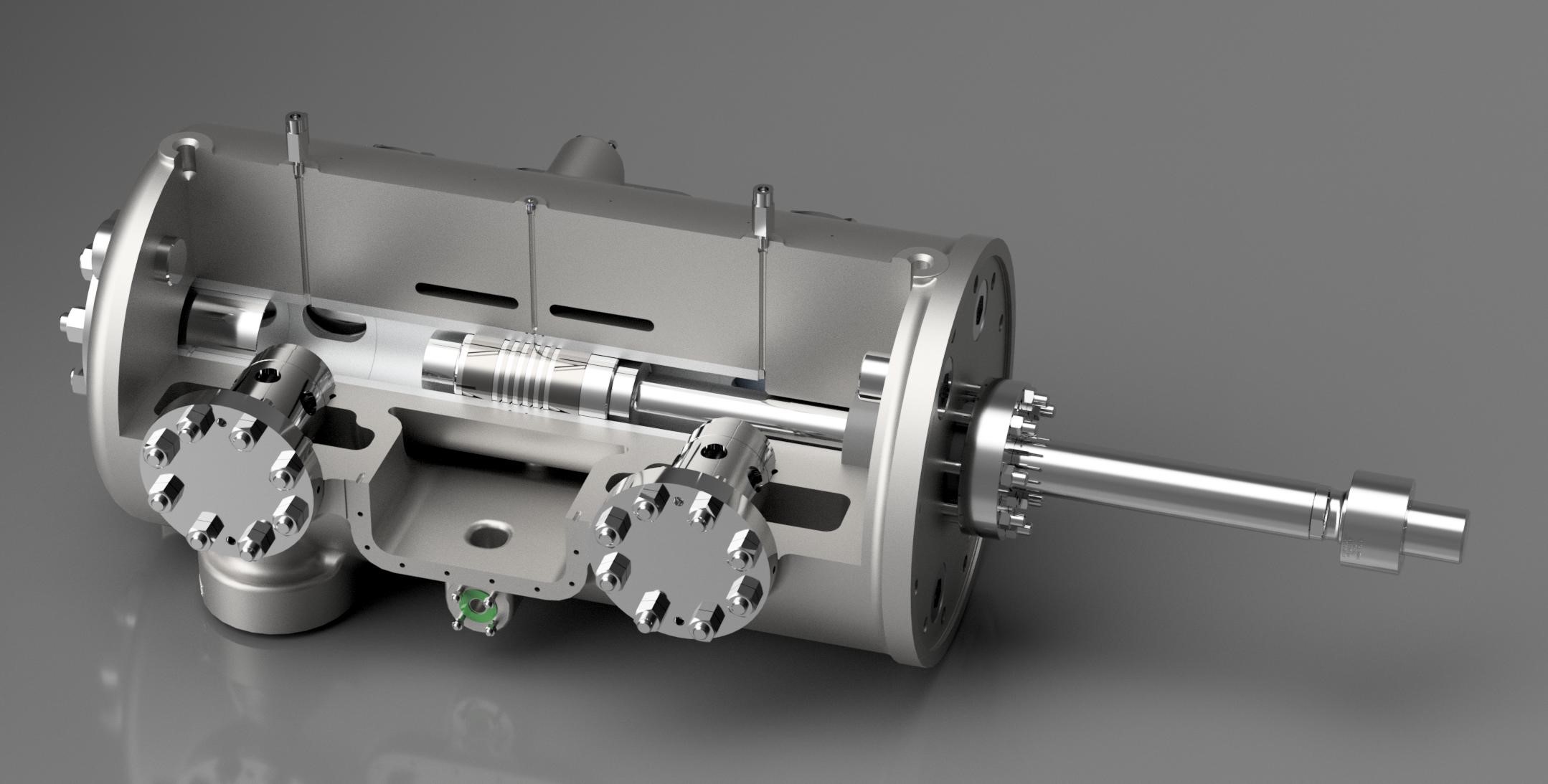

Capital spare parts

At Psicon, our state-of-the-art engineering and manufacturing expertise enables us to skilfully design and produce complex capital spare parts. Our range includes but is not limited to compressor cylinders and crankshafts, steam turbine and turbo compressor rotors, as well as compressor impellers, diaphragms, and blade carriers. Our team has a proven track record in designing and manufacture capital spare parts compatible with a wide array of OEM equipment.

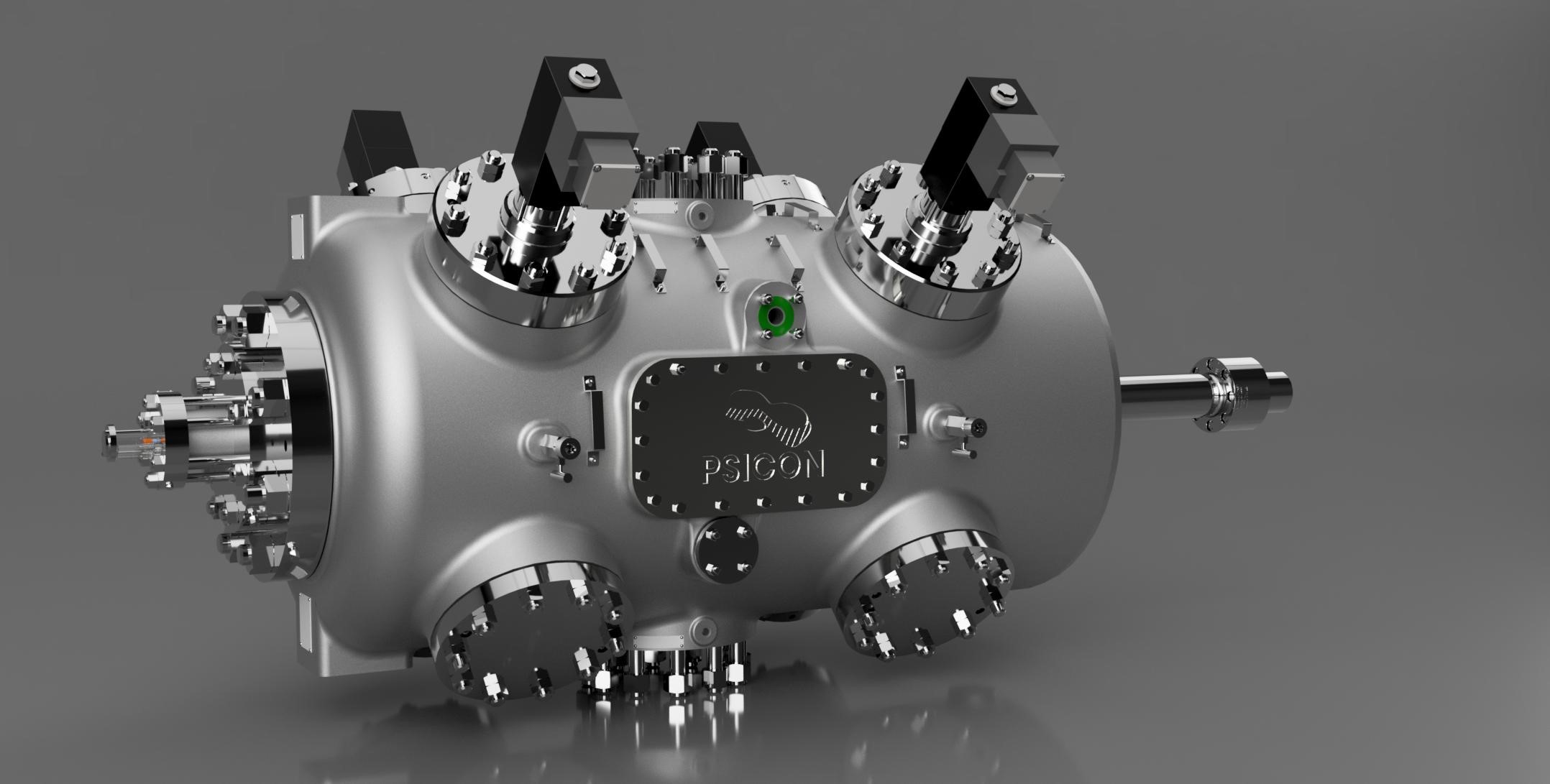

RECOMPRESS

RECOMPRESS brings the optimization and revitalization of compressor installations to the highest standard in the business. From the process design of the complete installation to compressor parts & hardware to the.

For our compressor upgrading services we operate closely with ACI Services Inc based in Cambridge, Ohio, USA.

Psicon and ACI Services operate worldwide under the brand name Recompress. With Recompress we combine the unique services of both companies enabling our customers to benefit from the combination of compressor design experts with a seasoned compressor packager.

Not always it is realized what type of upgrading solutions are available to upgrade or improve compressor operations, certainly with aging compressor installation process parameters, operation requirements and safety standards might have changed.

We offer best in class compressor capacity devices, a line of volume and unloading devices. We also supply a range of actuators for reduced volume demands, variable operating pressures, and reduced discharge pressures. We have our own fabrication and packaging facilities in multiple locations around the globe with our own certified crew and supply agreements with major reciprocating compressor OEM’S.

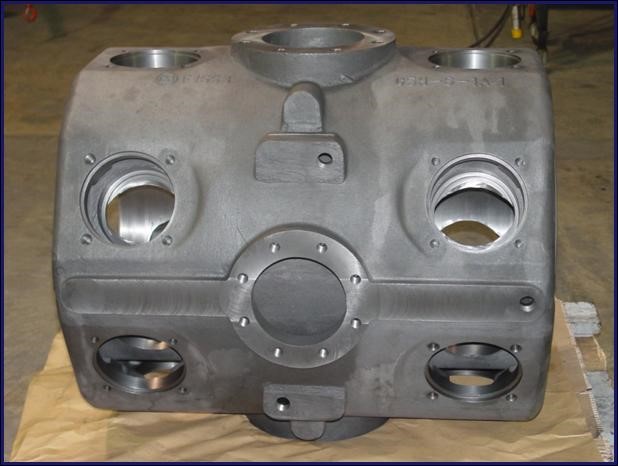

Reverse Engineering and 3D Scanning

Psicon has a modern reverse engineering department supported by state-of-the-art 3D scanning tools and capabilities. We can reverse engineer any part of your reciprocating compressor or turbo machinery.

Manufacturing capabilities

Our workshop has all the CNC equipment to machine large cylinders, rotors, turbine and compressor housings etc.

Contact Psicon

For more information about our products and services, please contact us.