Reverse Engineering and 3D Scanning

For many of our modernization, upgrading or replacement projects we need 3D scanning and reverse engineering capabilities. For example for some projects not all technical and design information is available and/or outdated. In addition, often customers ask us to deliver spare parts for obsolete equipment, worn out equipment, etc. Finally, we also get involved in new capital spare parts replacement projects directly in competition with the OEM due to long delivery times and inflated prices by the OEM.

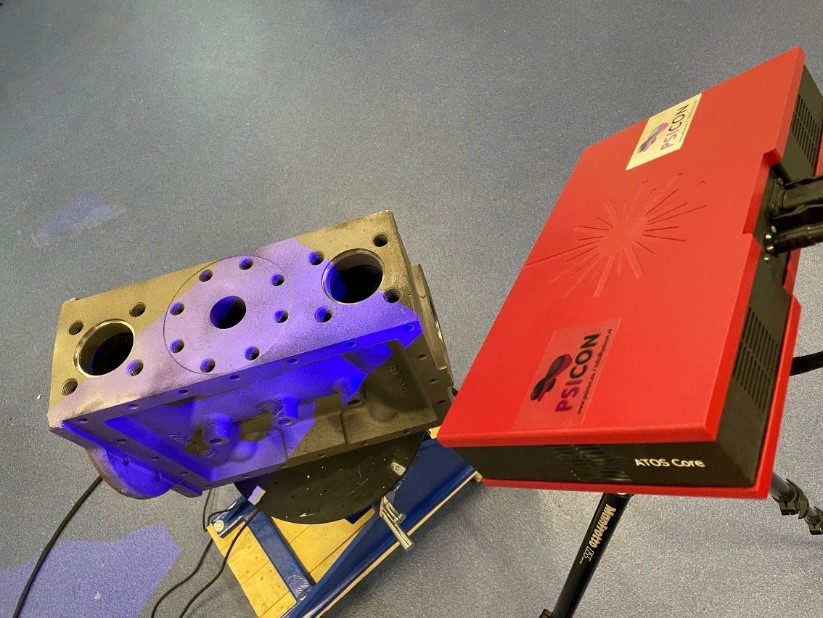

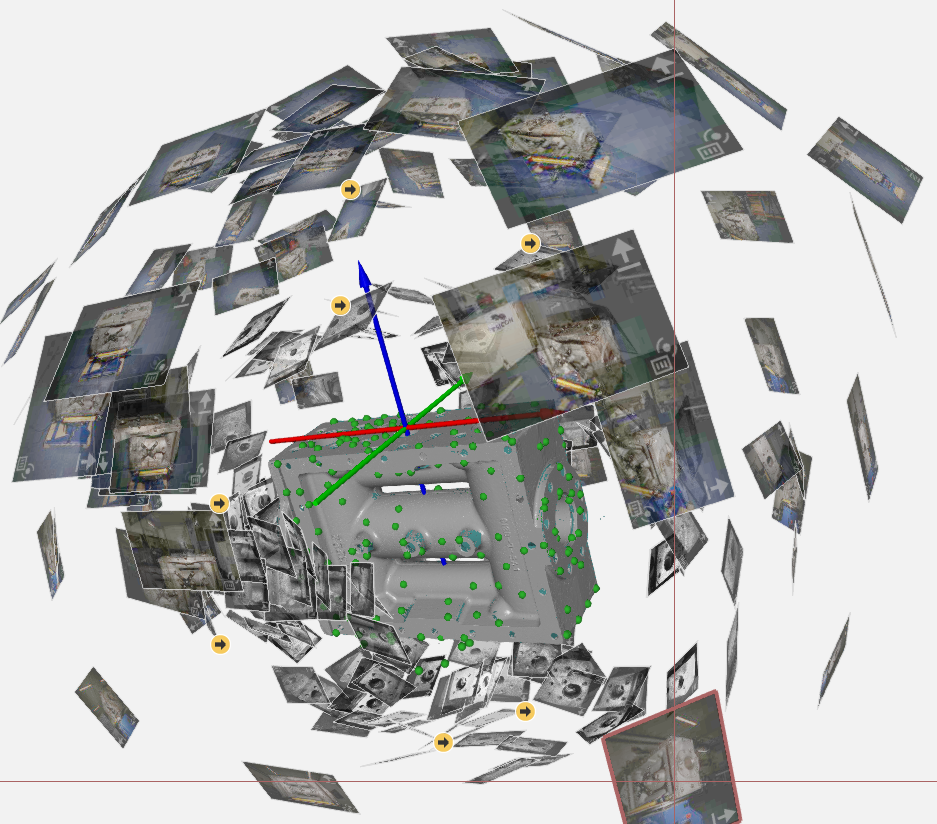

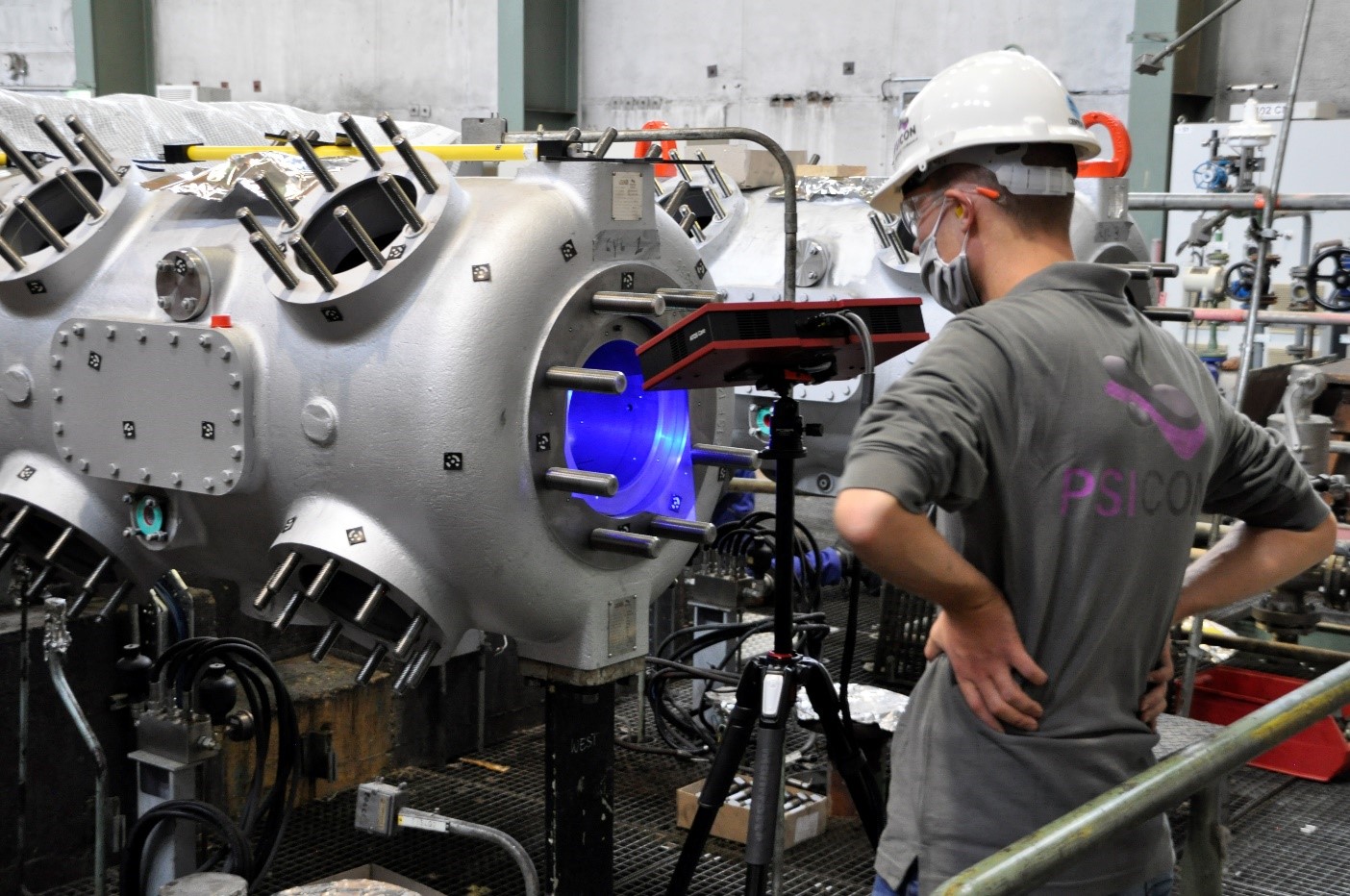

To allow us to model the equipment, make improved designs and equipment modernization Psicon has invested in state-of-the-art 3D scanning equipment.

We can scan small parts like a Sundyne impeller to complete steam turbine driven compressor trains.

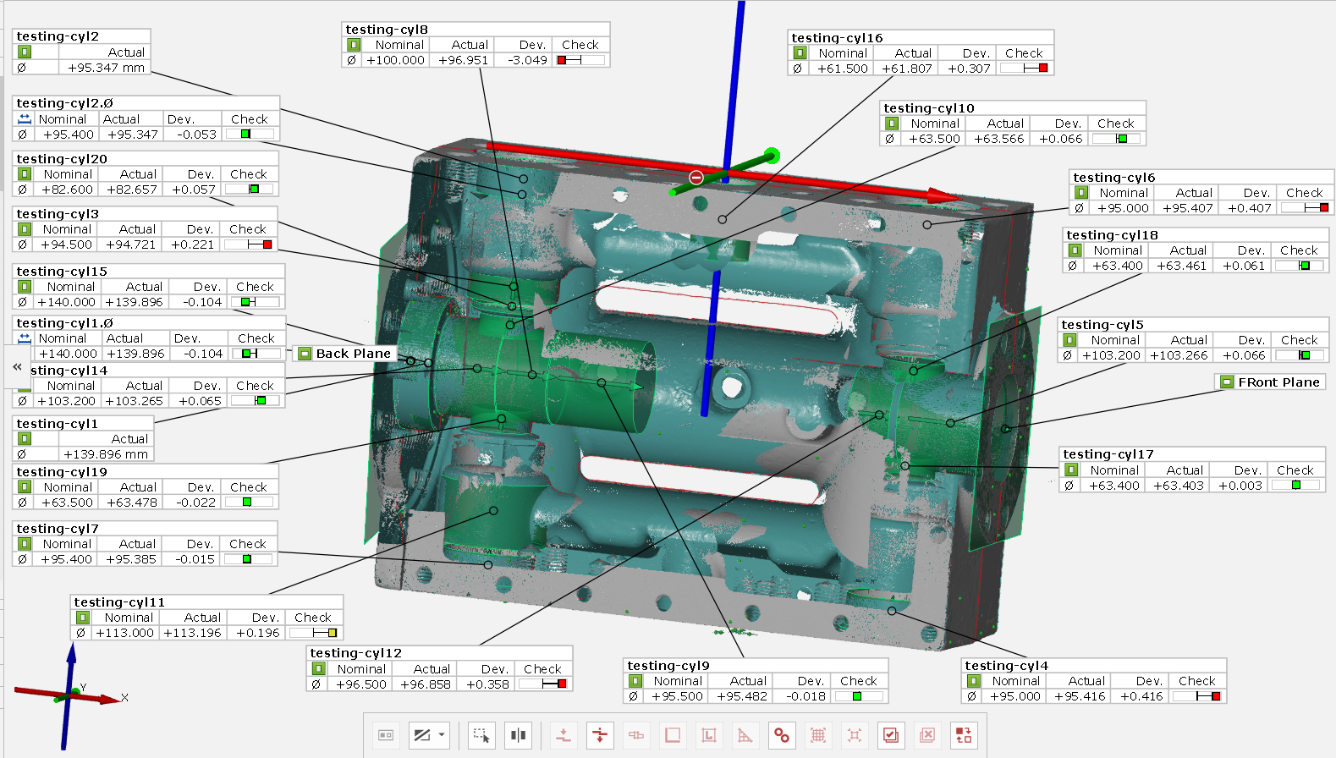

Besides the 3D scanning equipment we have all necessary software and know-how to make 3D models, advanced flow path calculations, pressure calculations, Finite Element Analysis (FEA), etc

Examples

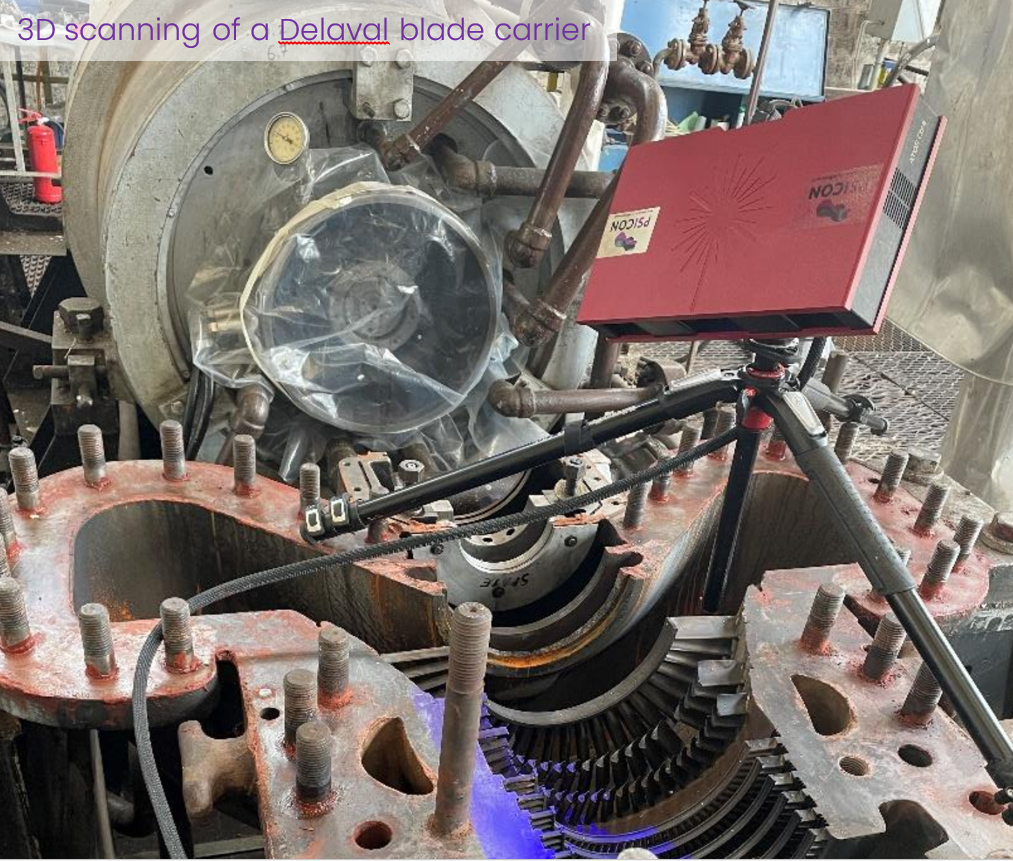

Psicon has an extensive experience with 3D scanning and reverse engineering of capital equipment. From large installations to small parts

Examples of parts we have scanned, designed and manufactured:

- complete compressor stations

- compressor rotors

- steam turbine rotors

- blade carriers

- reciprocating compressor cylinders/crossheads/crankshafts

- diaphragms

- compressor and turbine blades

Scanning equipment

We have the following 3D measuring systems available:

ZEISS – GOM Tritop – is a portable optical 3D coordinate CMM 3measuring system capable of precise measurements of large objects

ZEISS – GOM Atos Core – is a portable 3D high definition measurement system capable of making scans with tolerances below 0,01mm