Turbo Machinery modernization and upgrading

We offer complex modernization of rotating machines such as steam turbines, compressors, expanders and blowers to restore original or improved operating parameters. We also provide complex reconstruction of existing machines and improvements of its parameters (revamp, retrofit).

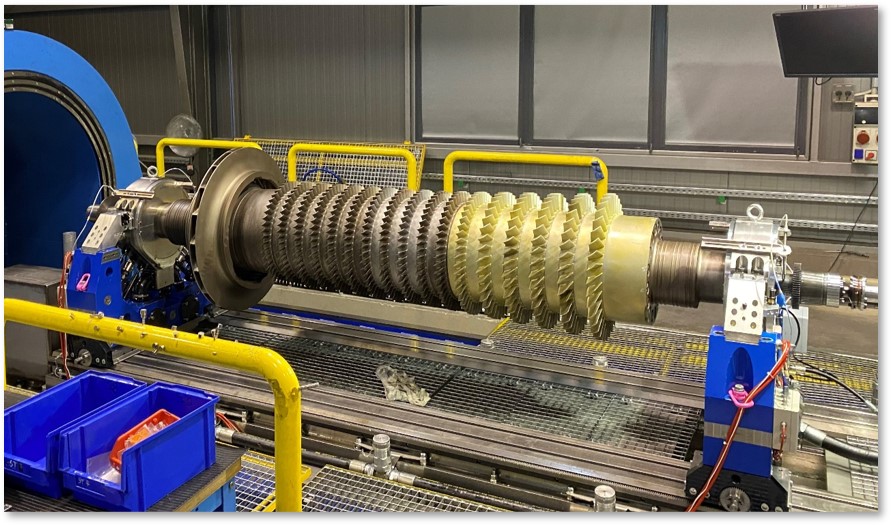

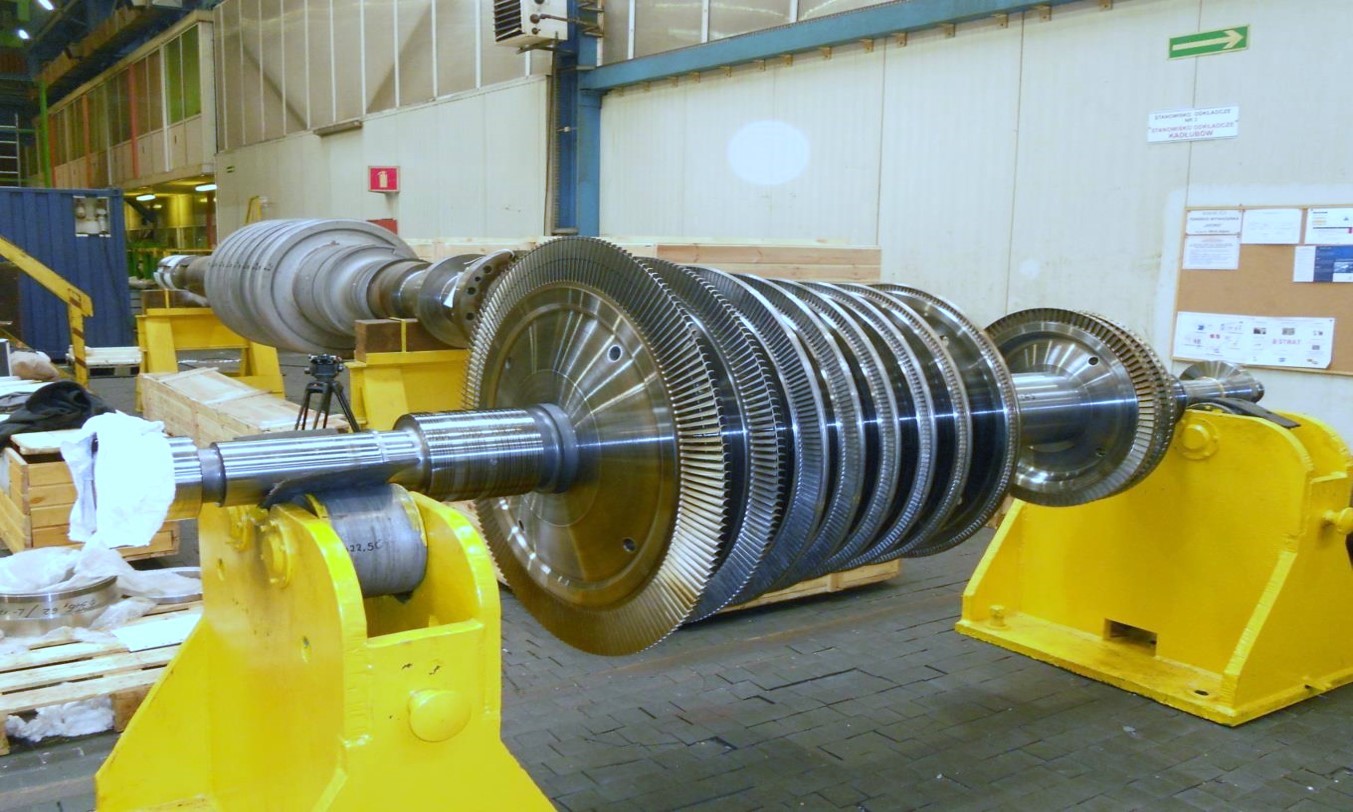

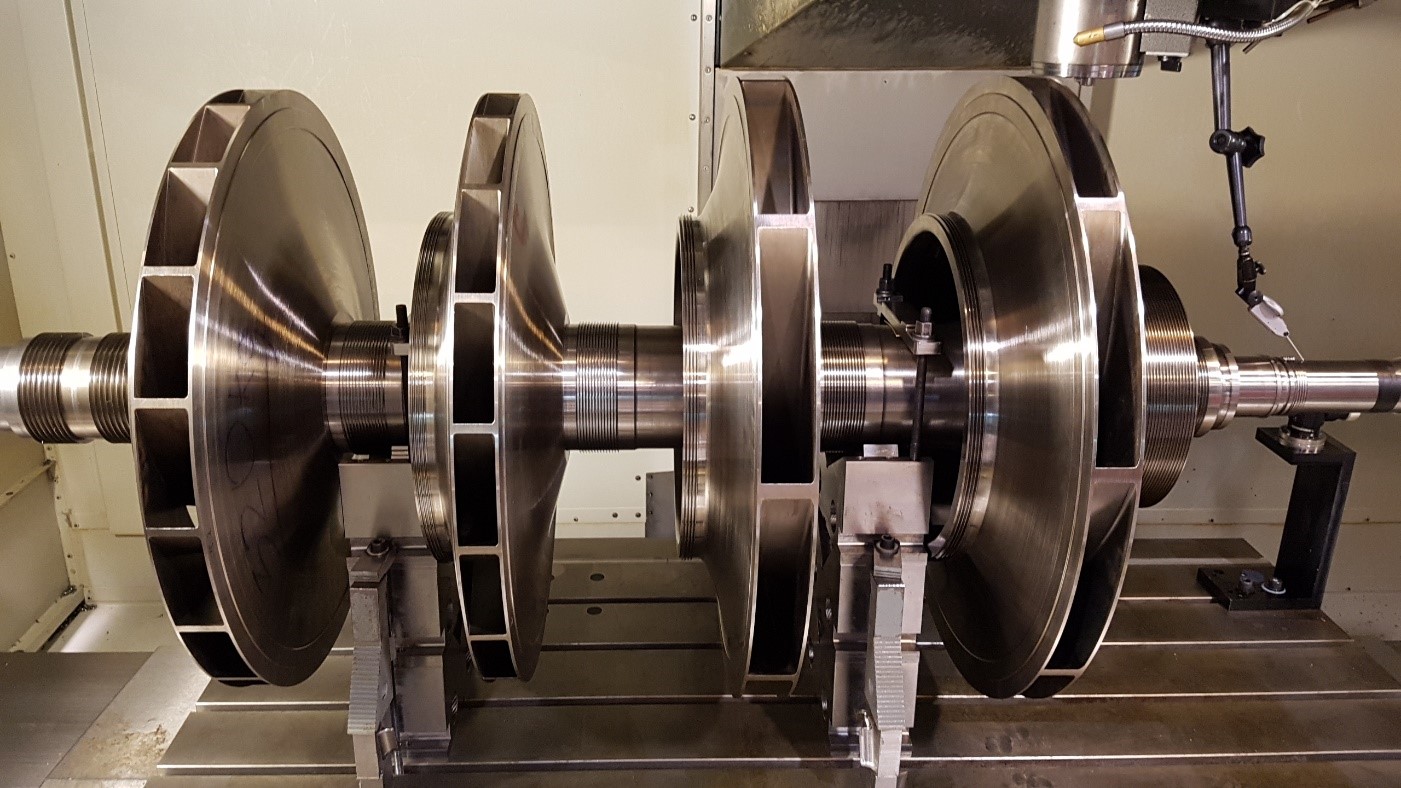

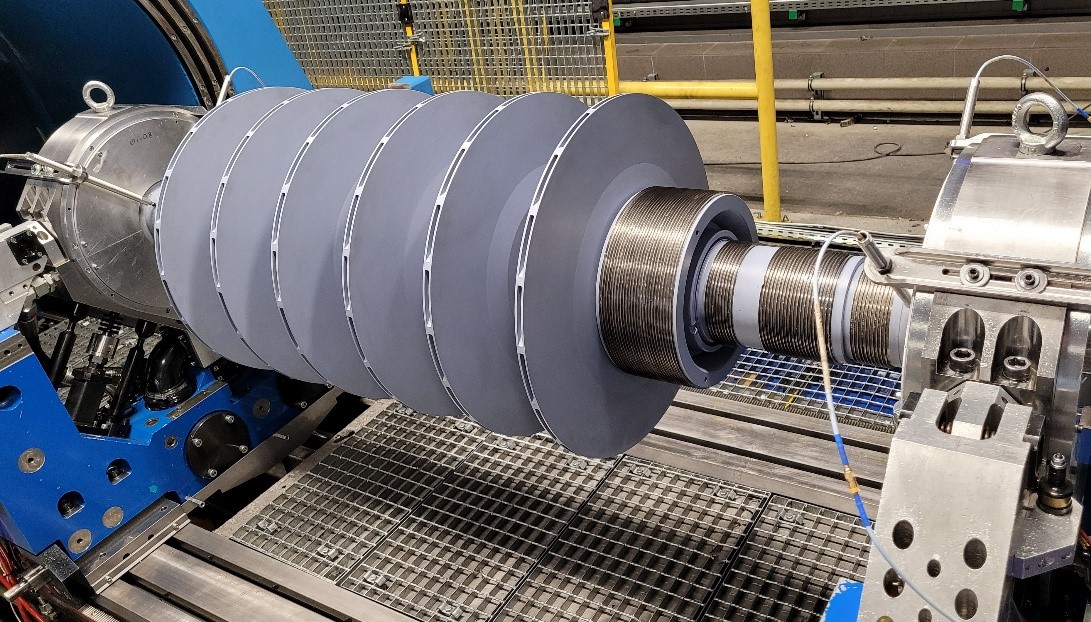

We also perform extensive modernization of machineries in order to regain or improve their performance (retrofit, revamp) in framework of which we deliver complete rotors. In addition, we implement modern technologies in terms of sealings, bearings, controls, anti-surge or governing system.

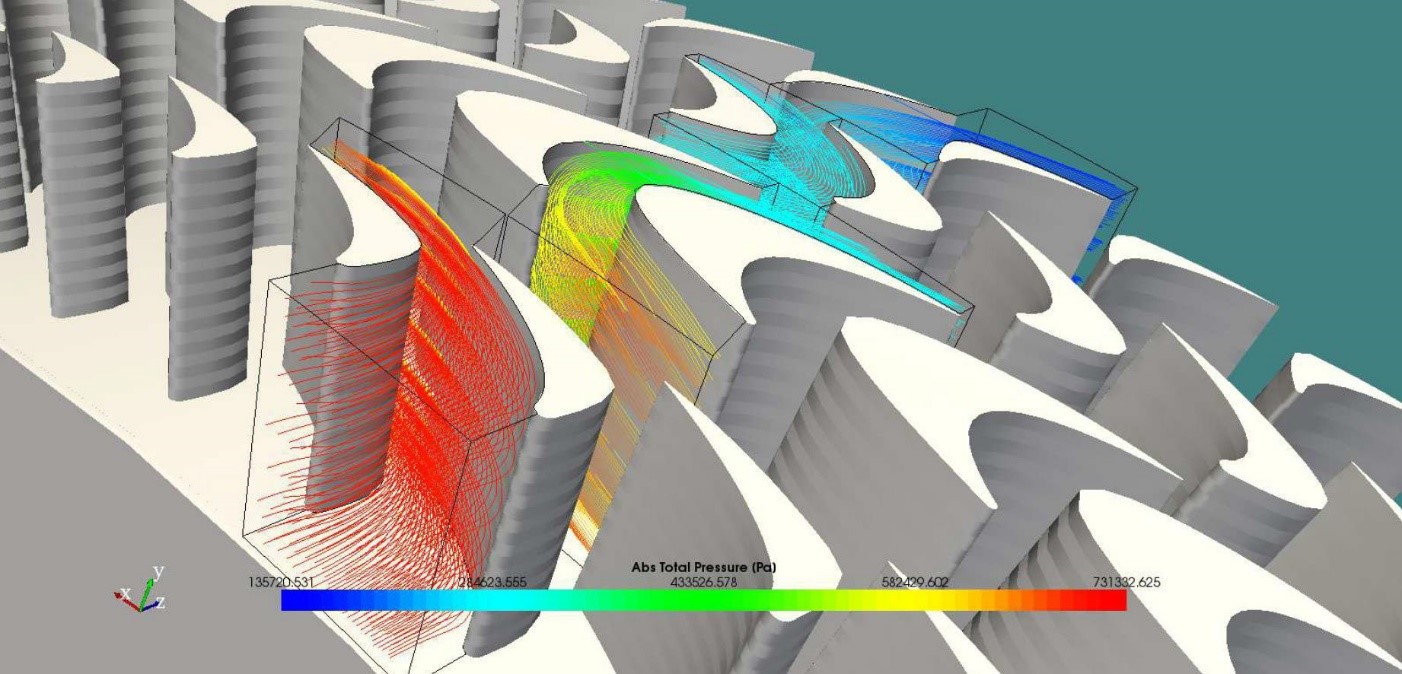

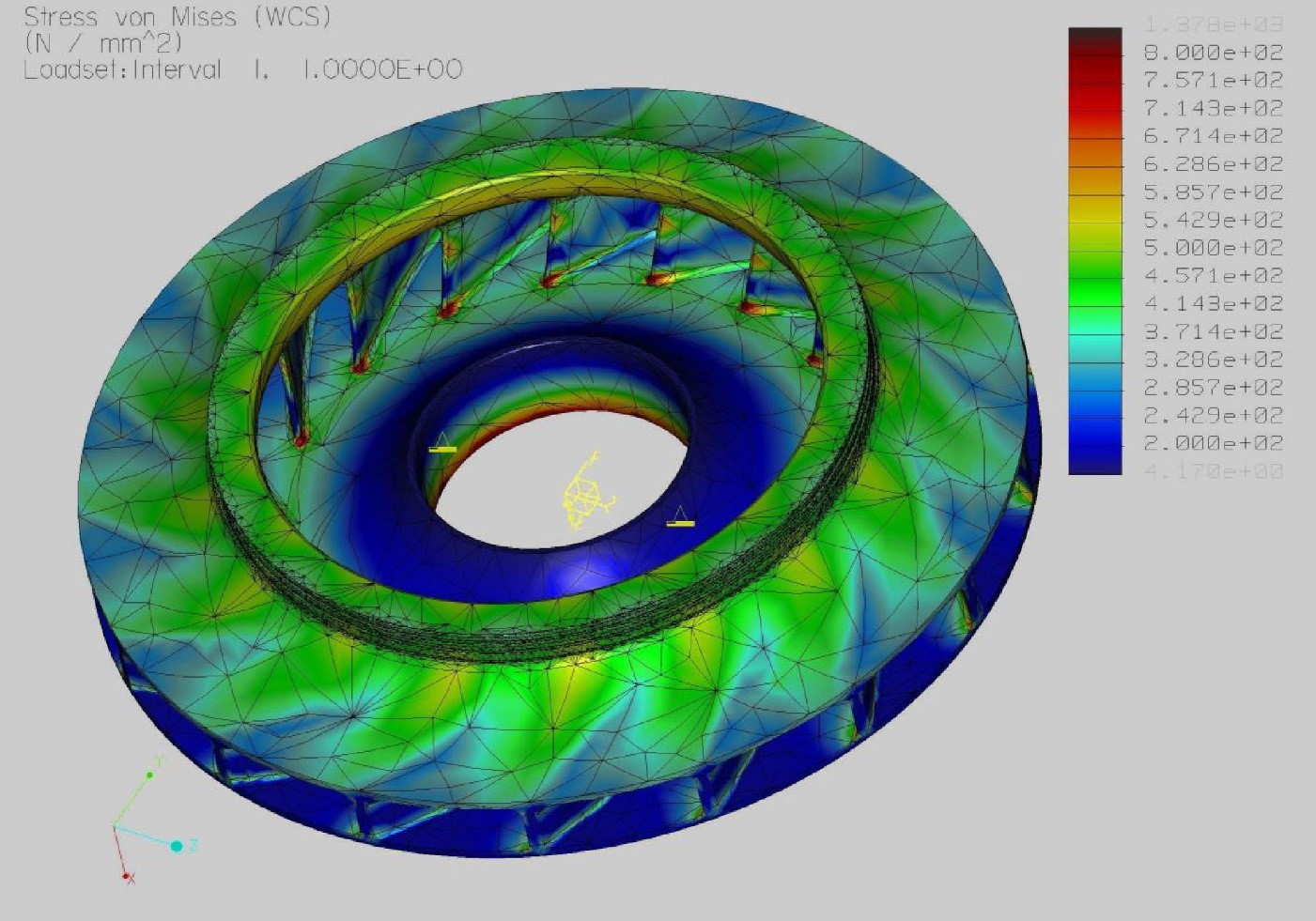

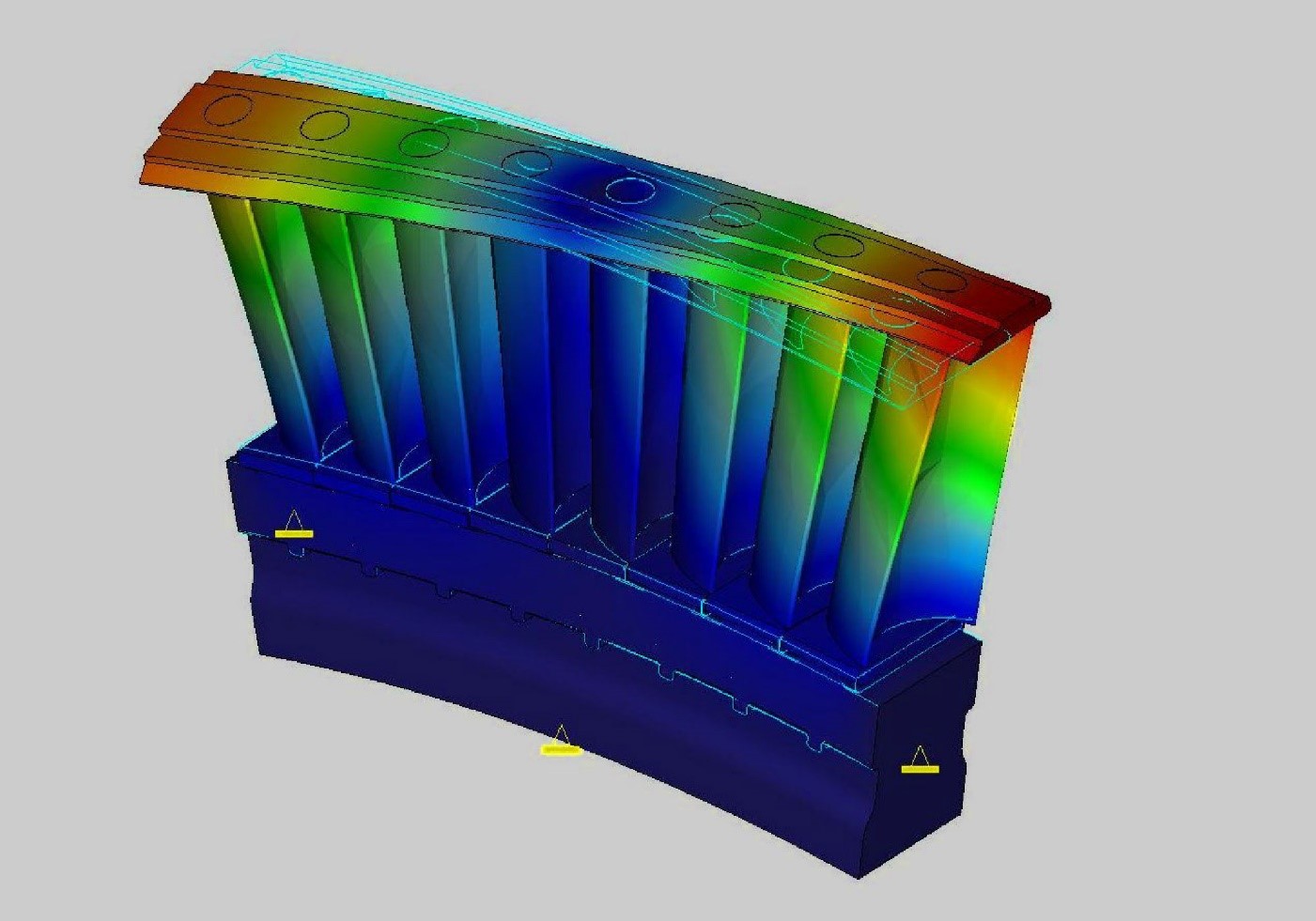

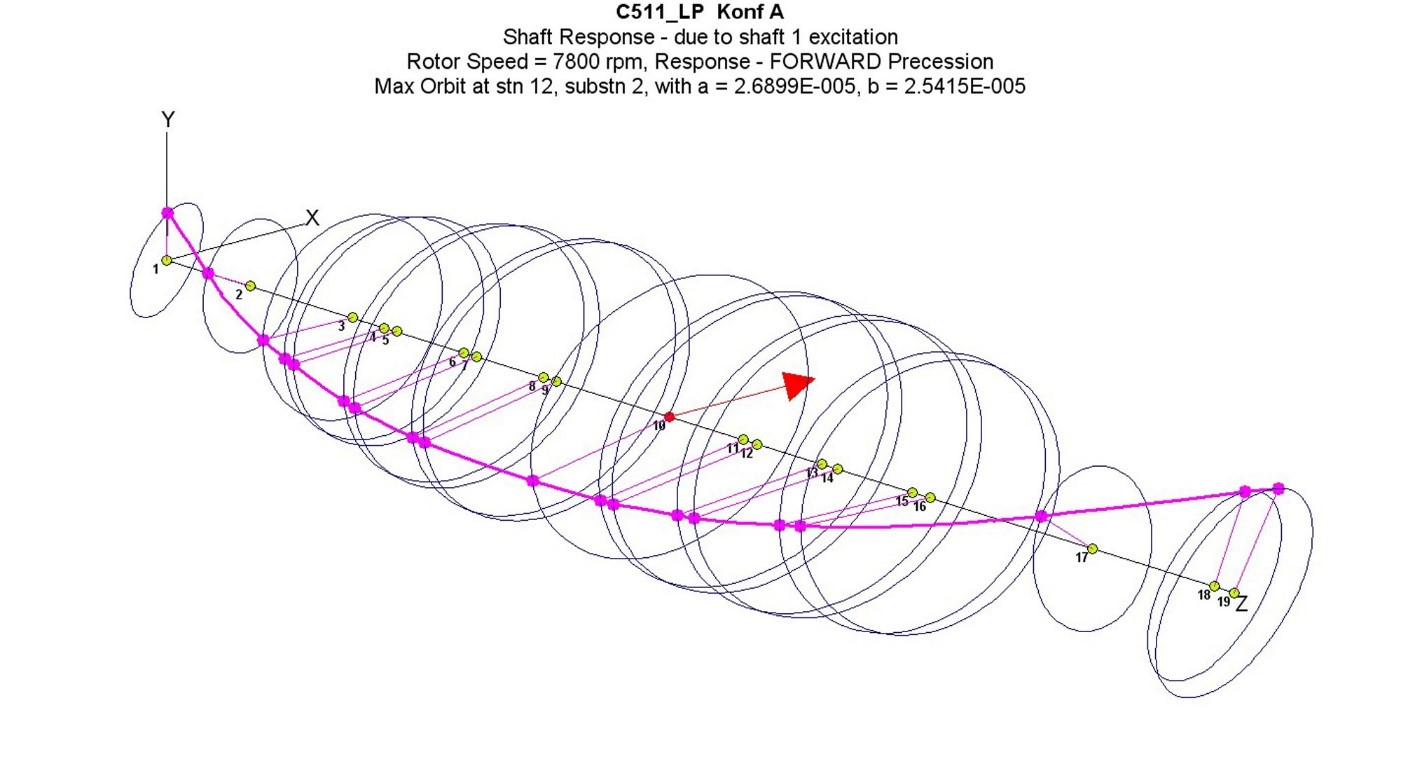

We offer a wide range of professional engineering services such as: stress analysis, dynamic- and aerodynamic calculations, flow path analysis. Reverse engineering and precise measurements of components with the use of the most modern measuring machines and software.

Solutions

- Compressor retrofits & rejuvenation

- Rotor repairs

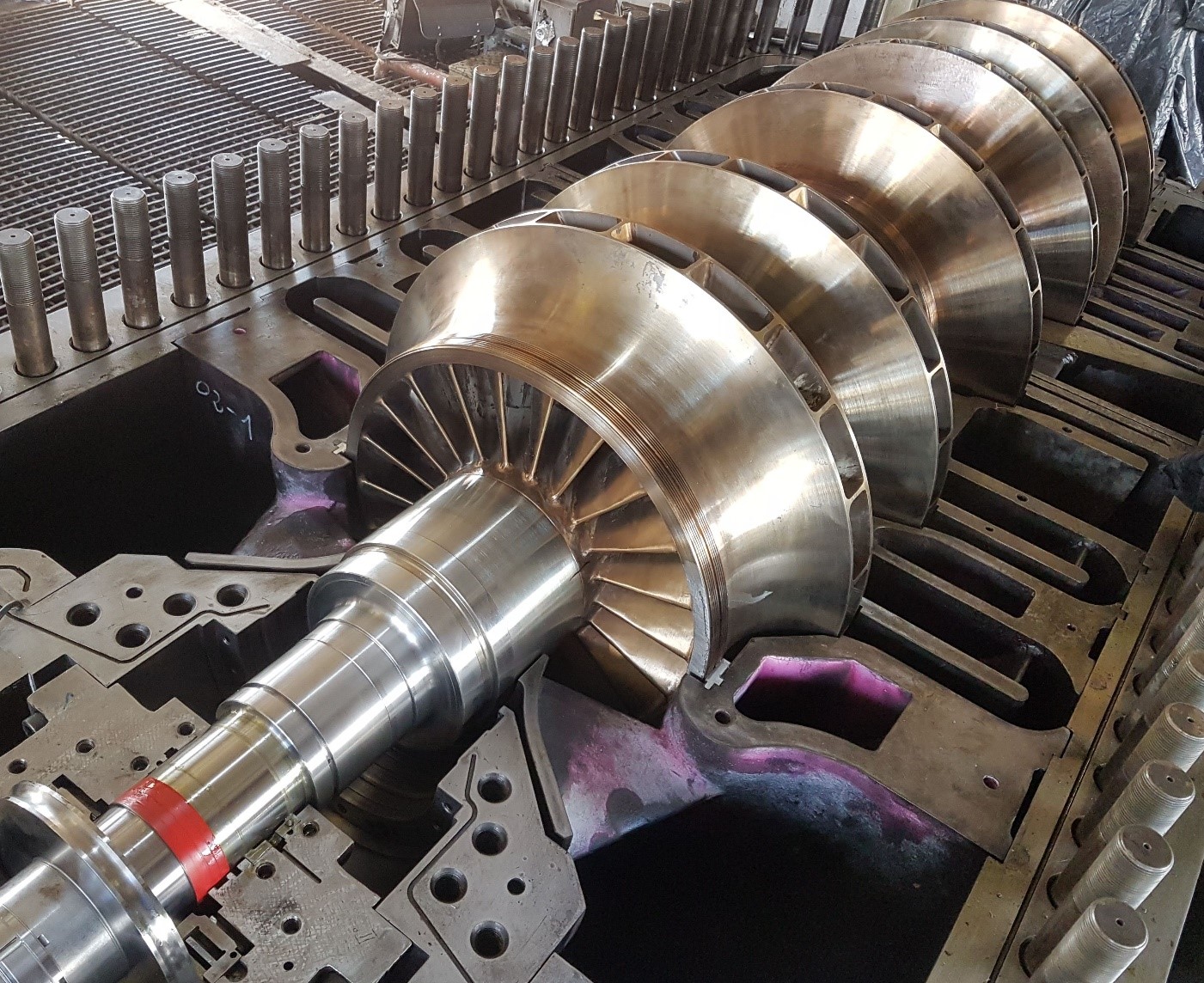

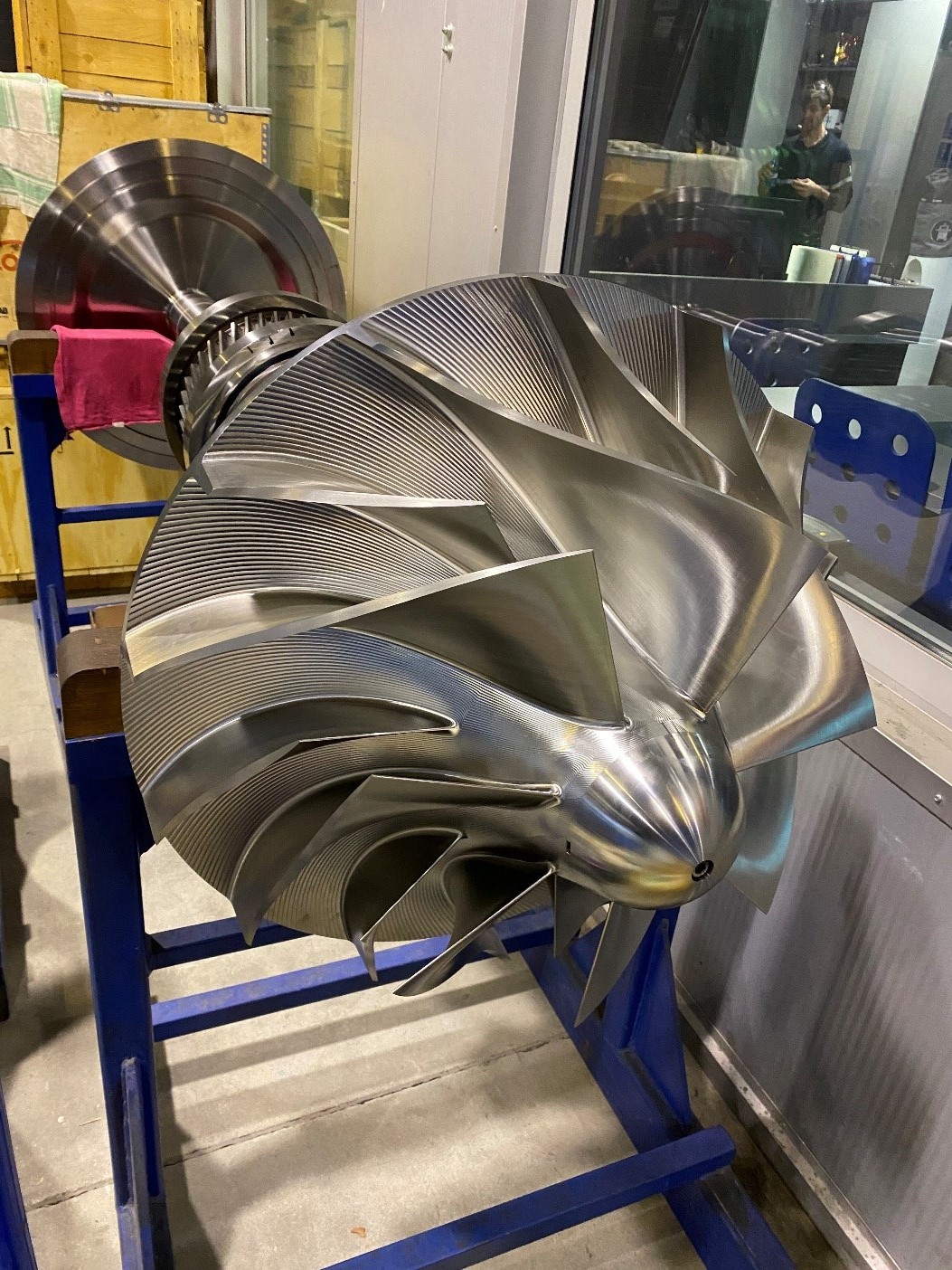

- Impeller design & manufacturing

- Advanced coatings for impellers

- Turbine and compressor casing repairs and manufacturing

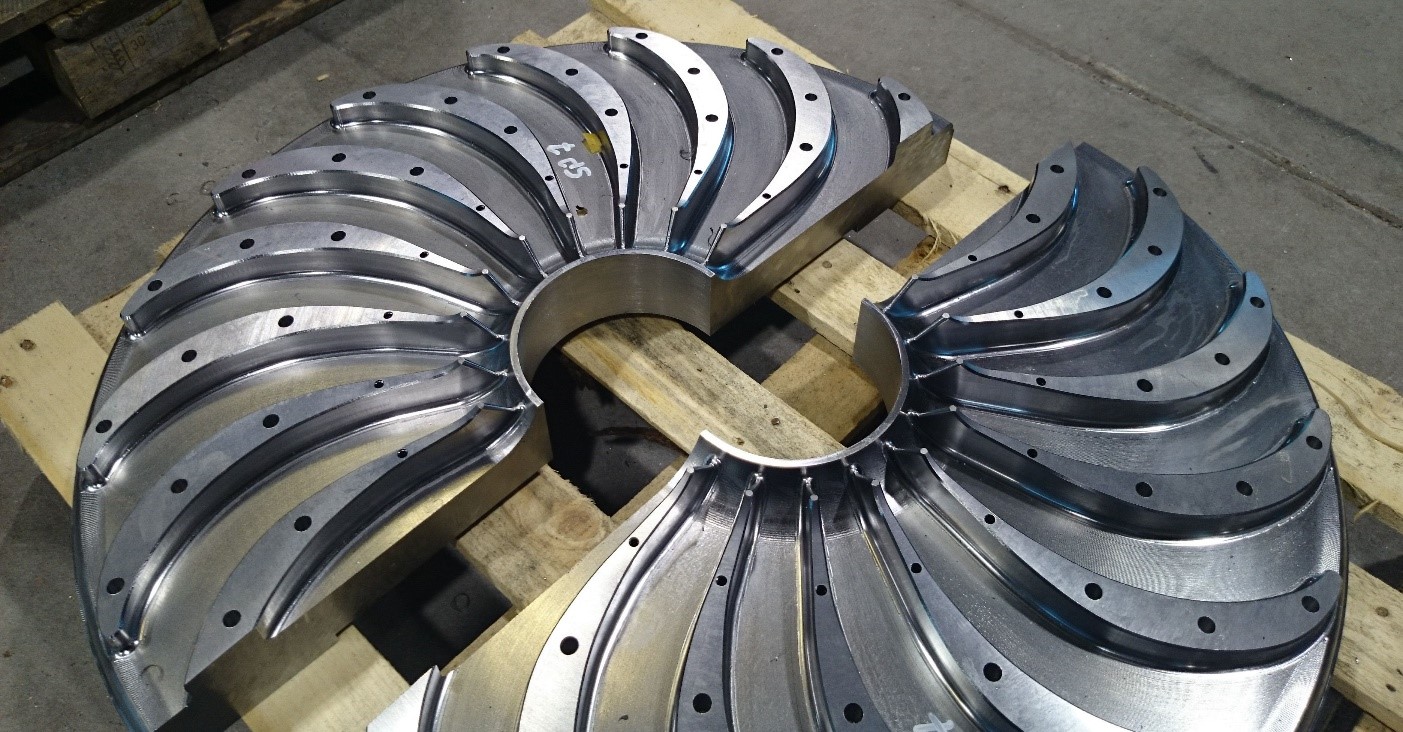

- Blade carrier repairs and manufacturing

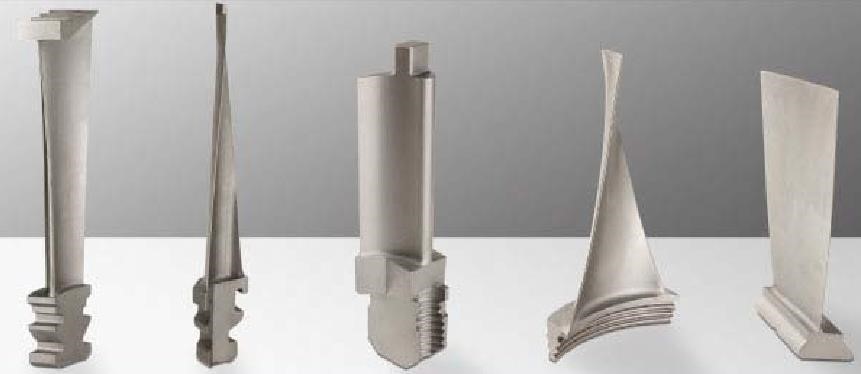

- Manufacturing of stationary or rotary blades

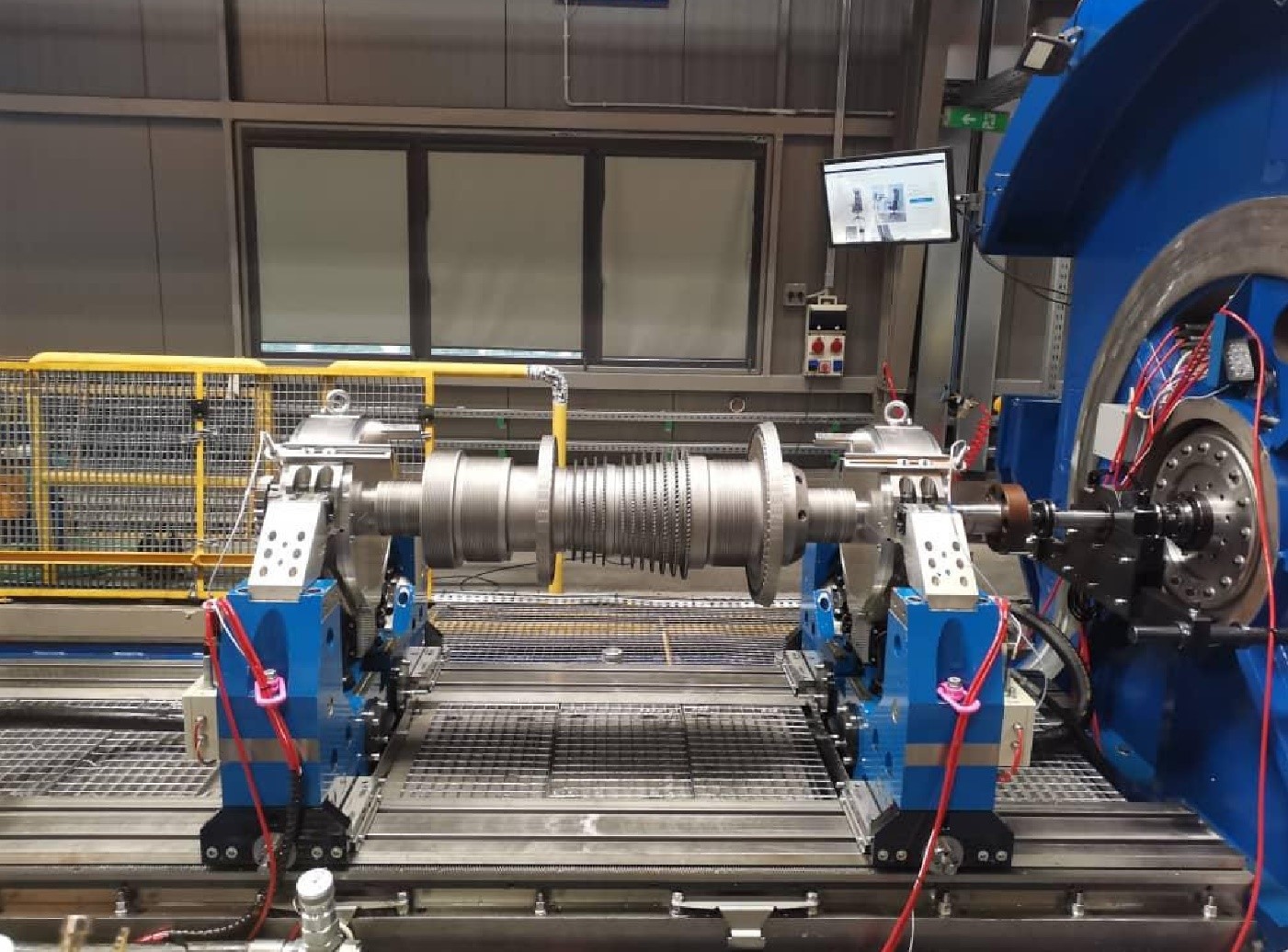

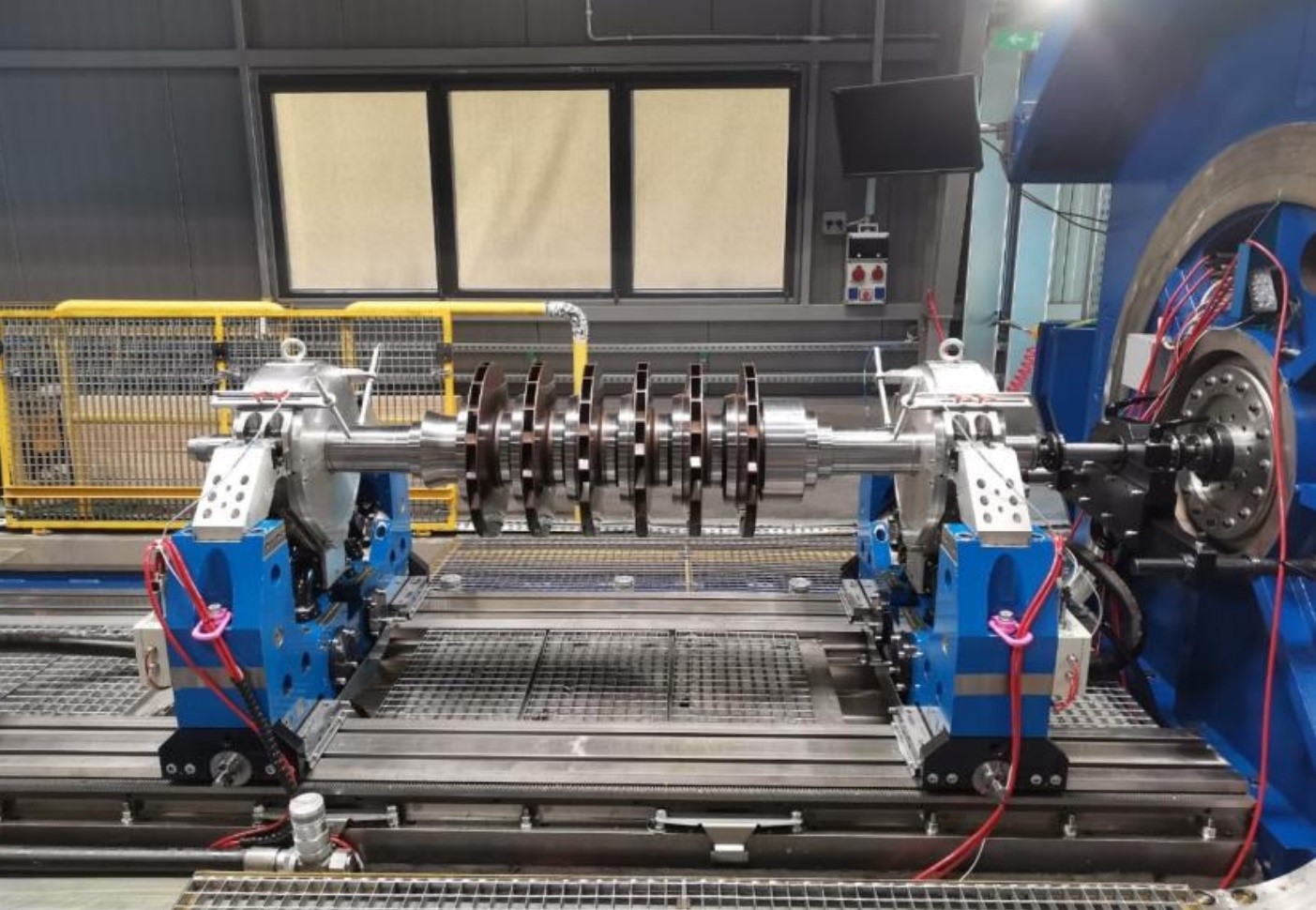

- High and low speed balancing

- Spin test compressor impellers

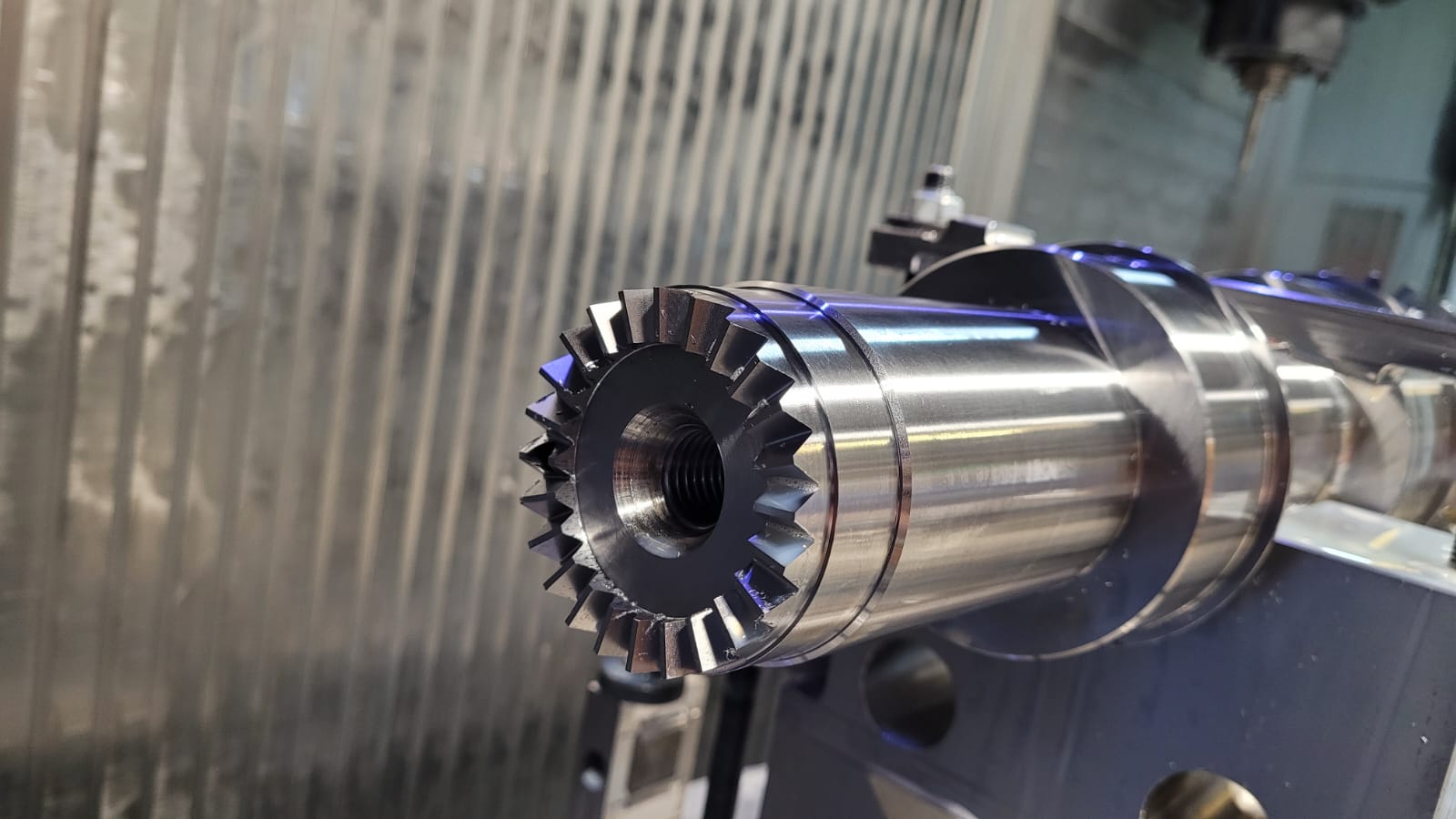

- Design and manufacturing of Hirth couplings or Curvic couplings

- Process debottlenecking

- Process simulations

- Training & 3rd Party consultancy

Modernization

We offer complex modernization of rotating machines such as steam turbines, compressors, expanders and blowers to restore original or improved operating parameters. We also provide complex reconstruction of existing machines and improvements of its parameters (revamp, retrofit).

We also perform extensive modernization of machineries in order to regain or improve their performance (retrofit, revamp) in framework of which we deliver complete rotors. In addition, we implement modern technologies in terms of sealings, bearings, controls, anti-surge or governing system.

We offer a wide range of professional engineering services such as: stress analysis, dynamic- and aerodynamic calculations, flow path analysis. Reverse engineering and precise measurements of components with the use of the most modern measuring machines and software.

Rotor and Stationary Parts Repair

Our workshop we will support any rotor or stationary parts repair possible.

All our repairs are done as per API 687 standards.

Scope of rotor repairs:

- Impeller repairs

- Journal repairs

- Seal strip replacement

- Seal sleeve replacement

- Thrust disc and hardware replacement

- Reblading

- High and low speed balancing

- Impeller spin test

- Advanced coatings

Scope of stationary parts repairs:

- Diaphragm bucket or vane repairs

- Inlet guide vane repairs

- Reblading of axial compressor or steam turbine blade carriers

- Seal strip replacement

- Labyrinth replacement

- Turbine casing repairs

Gear type compressor:

We are able to supply new pinion shafts and impellers with hirth coupling connection including spin test and incremental balancing.

All parts required for the repairs are designed and manufactured in our workshop ensuring the fastest repairs against the highest quality standards.

Reverse Engineering and 3D Scanning

Psicon has a modern reverse engineering department supported by state-of-the-art 3D scanning tools and capabilities. We can reverse engineer any part of your reciprocating compressor or turbo machinery.

Manufacturing capabilities

Our workshop has all the CNC equipment to machine large cylinders, rotors, turbine and compressor housings etc.

Contact Psicon

For more information about our products and services, please contact us.